ΝΙΚΑ-Siri S12® RSB ropes are 12 strands High Modulus / High-Performance ropes with excellent properties, ideal for the heavy shipping industry. They are manufactured using the highest quality UHMWPE fibers.

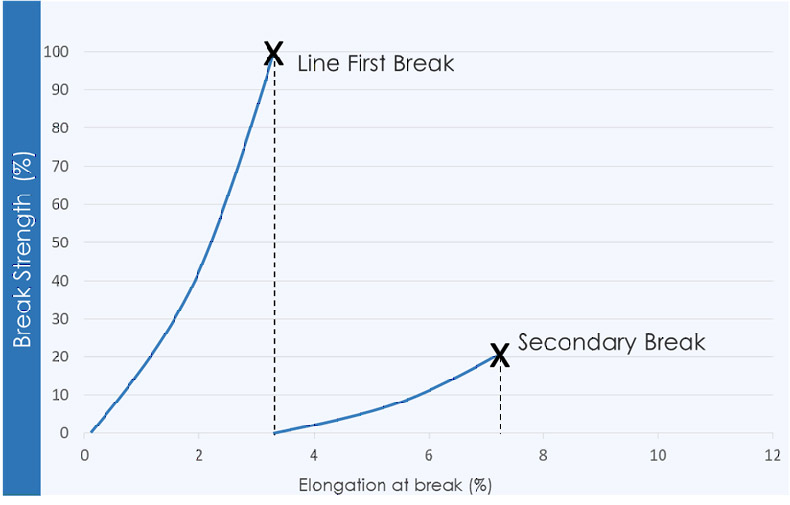

The reduced recoil effect is accomplished with the use of an inner-braid rope structure that will enable the restraining of snap-back release in case of partition. Due to the different elongation properties of the primary rope member and the RSB member, the recoiling of the rope is reduced, which increases the safety onboard.

ΝΙΚΑ-Siri S12® RSB ropes are 7 times stronger than steel ropes and 3 times stronger than polyester (on a weight by weight comparison).

The application of NikaThane coating and the Linear Structural Preformation (LSP) process improve drastically the structural stability and the strength efficiency of the rope while increasing the rope’s coefficient of friction for better gripping performance when used in winches, capstans, chocks, bitts, etc. When compared to wire ropes, ΝΙΚΑ-Siri S12® RSB ropes are stronger (for the same weight), lighter (making them easy and fast to handle), safer to use, and cost-saving (minimum maintenance needs, no greases, faster operating times).

The two-step partition of the rope is attributed to the RSB member that exhibits higher elongation and restraints the extreme snap-back effect when the rope is stretched to break.

| Size (Diam) | Weight | MBL | LDBF | |

|---|---|---|---|---|

| mm | Kilos /100m | Kilos /220m | tn | tn |

| 19 | 25,6 | 56,4 | 36,4 | 33,1 |

| 21 | 28,4 | 62,5 | 45,1 | 41,0 |

| 23 | 33,2 | 73,1 | 48,4 | 44,0 |

| 25 | 38,4 | 84,6 | 56,7 | 51,6 |

| 27 | 46,3 | 101,9 | 66,4 | 60,4 |

| 29 | 53,4 | 117,4 | 77,6 | 70,5 |

| 31 | 62,1 | 136,7 | 91,5 | 83,1 |

| 33 | 67,5 | 148,4 | 99,9 | 90,8 |

| 35 | 73,3 | 161,3 | 109,2 | 99,3 |

| 37 | 81,1 | 178,4 | 121,6 | 110,5 |

| 39 | 95,2 | 209,4 | 136,0 | 123,6 |

| 41 | 103,9 | 228,6 | 149,9 | 136,3 |

| 43 | 114,7 | 252,4 | 167,0 | 151,8 |

| 45 | 124,1 | 273,0 | 181,9 | 165,4 |

| 47 | 132,2 | 290,9 | 194,8 | 177,1 |

| 49 | 145,0 | 319,0 | 215,1 | 195,5 |

| 51 | 159,3 | 350,5 | 233,0 | 211,9 |

| 54 | 164,0 | 360,8 | 240,5 | 218,6 |

| 58 | 194,3 | 427,5 | 288,6 | 262,4 |

| 62 | 218,2 | 480,1 | 314,4 | 285,8 |

MBL: Minimum Breaking Load (as per ISO 2307)

LDBF: Line Design Break Force (as per MEG4)

Subscribe to our newsletter

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our Cookie Policy.