At Katradis Marine Ropes Industry, we offer a premium range of High-Performance Shackles designed for mooring, towing, lifting, and aquaculture operations. Our shackles are engineered for both commercial and non-critical applications, ensuring durability, strength, and safety in various marine and industrial environments.

Types of Shackles We Offer

Applications of Our Shackles

Crafted from alloy steel pins and high-carbon, hot-dip galvanized bodies, Katradis HP Shackles offer proven superior durability and corrosion resistance. With a 6:1 safety factor (MBL to WLL ratio), these shackles offer an increased safety level for a long service time for any applications used as long as operation, storage, inspection & maintenance are properly conducted. Each shackle is proof load tested at 2:1 of its WLL and permanently marked for easy selection.

Key Features:

For optimal performance (100% WLL), forces should always remain perpendicular to the pin to ensure full utilization of the WLL. For vertical and angled loading please choose anchor shackle (Bow type), chain shackle (“D” type) is for vertical loading only (00 angle to the vertical).

Sideways loading (forces perpendicular to the shackle’s body sides {parallel to the pin}) is not recommended.

Temperature will affect shackle’s WLL.

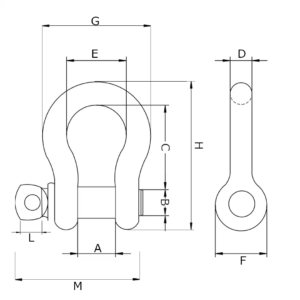

| Nominal Size (in.) D | Weight Each (kg) | Dimensions (mm) | Working Load Limit (tons) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | L | M | P | |||

| 3/16 | 0,03 | 9,65 | 6,35 | 22,4 | 4,85 | 15,2 | 14,2 | 24,9 | 37,3 | 4,06 | 28,4 | 4,85 | 0,33 |

| 1/4 | 0,05 | 11,9 | 7,85 | 28,7 | 6,35 | 19,8 | 15,5 | 32,5 | 46,7 | 4,85 | 35,1 | 6,35 | 0,50 |

| 5/16 | 0,09 | 13,5 | 9,65 | 31,0 | 7,85 | 21,3 | 19,1 | 37,3 | 53,0 | 5,60 | 42,2 | 7,85 | 0,75 |

| 3/8 | 0,14 | 16,8 | 11,2 | 36,6 | 9,65 | 26,2 | 23,1 | 45,2 | 63,0 | 6,35 | 51,5 | 9,65 | 1 |

| 7/16 | 0,17 | 19,1 | 12,7 | 42,9 | 11,2 | 29,5 | 26,9 | 51,5 | 74,0 | 7,85 | 60,5 | 11,2 | 1,5 |

| 1/2 | 0,33 | 20,6 | 16,0 | 47,8 | 12,7 | 33,3 | 30,2 | 58,5 | 83,5 | 9,65 | 68,5 | 12,7 | 2,0 |

| 5/8 | 0,62 | 26,9 | 19,1 | 60,5 | 16,0 | 42,9 | 38,1 | 74,5 | 106 | 11,2 | 85,0 | 17,5 | 3,25 |

| 3/4 | 1,07 | 31,8 | 22,4 | 71,5 | 19,1 | 51,0 | 46,0 | 89,0 | 126 | 12,7 | 101 | 20,6 | 4,75 |

| 7/8 | 1,64 | 36,6 | 25,4 | 84,0 | 22,4 | 58,0 | 53,0 | 102 | 148 | 12,7 | 114 | 24,6 | 6,5 |

| 1 | 2,28 | 42,9 | 28,7 | 95,5 | 25,4 | 68,5 | 60,5 | 119 | 167 | 14,2 | 129 | 26,9 | 8,5 |

| 1-1/8 | 3,36 | 46,0 | 31,8 | 108 | 29,5 | 74,0 | 68,5 | 131 | 190 | 16,0 | 142 | 31,8 | 9,5 |

| 1-1/4 | 4,31 | 51,5 | 35,1 | 119 | 32,8 | 82,5 | 76,0 | 146 | 210 | 17,5 | 156 | 35,1 | 12 |

| 1-3/8 | 6,14 | 57,0 | 38,1 | 133 | 36,1 | 92,0 | 84,0 | 162 | 233 | 19,1 | 174 | 38,1 | 13,5 |

| 1-1/2 | 7,80 | 60,5 | 41,4 | 146 | 39,1 | 98,5 | 92,0 | 175 | 254 | 20,6 | 187 | 41,1 | 17 |

| 1-3/4 | 12,6 | 73,0 | 51,0 | 178 | 46,7 | 127 | 106 | 225 | 313 | 25,4 | 231 | 57,0 | 25 |

| 2 | 20,4 | 82,5 | 57,0 | 197 | 53,0 | 146 | 122 | 253 | 348 | 31,0 | 263 | 61,0 | 35 |

| 2-1/2 | 38,9 | 105 | 70,0 | 267 | 69,0 | 184 | 145 | 327 | 453 | 35,1 | 330 | 79,5 | 55 |

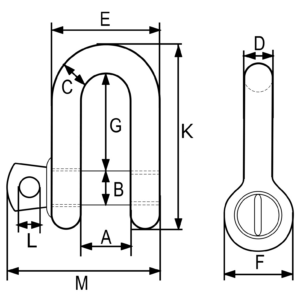

| Nominal Size (in.) D | Weight Each (kg) | Dimensions (mm) | Working Load Limit (tons) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | K | L | M | |||

| 1/4 | 0,05 | 11,9 | 7,85 | 6,35 | 6,35 | 24,6 | 15,5 | 22,4 | 40,4 | 4,85 | 35,1 | 0,50 |

| 5/16 | 0,08 | 13,5 | 9,65 | 7,85 | 7,85 | 29,5 | 19,1 | 26,2 | 48,5 | 5,60 | 42,2 | 0,75 |

| 3/8 | 0,13 | 16,8 | 11,2 | 9,65 | 9,65 | 35,8 | 23,1 | 31,8 | 58,5 | 6,35 | 51,5 | 1 |

| 7/16 | 0,20 | 19,1 | 12,7 | 11,2 | 11,2 | 41,4 | 26,9 | 36,6 | 67,5 | 7,85 | 60,5 | 1,5 |

| 1/2 | 0,27 | 20,6 | 16,0 | 12,7 | 12,7 | 46,0 | 30,2 | 41,4 | 77,0 | 9,65 | 68,5 | 2,0 |

| 5/8 | 0,57 | 26,9 | 19,1 | 15,7 | 16,0 | 58,5 | 38,1 | 51,0 | 95,5 | 11,2 | 85,0 | 3,25 |

| 3/4 | 1,20 | 31,8 | 22,4 | 20,6 | 19,1 | 70,0 | 46,0 | 60,5 | 115 | 12,7 | 101 | 4,75 |

| 7/8 | 1,43 | 36,6 | 25,4 | 24,6 | 22,4 | 81,0 | 53,0 | 71,5 | 135 | 12,7 | 114 | 6,5 |

| 1 | 2,15 | 42,9 | 28,7 | 25,4 | 25,4 | 93,5 | 60,5 | 81,0 | 151 | 14,2 | 129 | 8,5 |

| 1-1/8 | 3,06 | 46,0 | 31,8 | 31,8 | 28,7 | 103 | 68,5 | 91,0 | 172 | 16,0 | 142 | 9,5 |

| 1-1/4 | 4,11 | 51,5 | 35,1 | 35,1 | 31,8 | 115 | 76,0 | 100 | 191 | 17,5 | 156 | 12 |

| 1-3/8 | 5,28 | 57,0 | 38,1 | 38,1 | 35,1 | 127 | 84,0 | 111 | 210 | 19,1 | 174 | 13,5 |

| 1-1/2 | 7,23 | 60,5 | 41,4 | 41,1 | 38,1 | 137 | 92,0 | 122 | 230 | 20,6 | 187 | 17 |

| 1-3/4 | 12,1 | 73,0 | 51,0 | 54,0 | 44,5 | 162 | 106 | 146 | 279 | 25,4 | 231 | 25 |

| 2 | 19,2 | 82,5 | 57,0 | 60,0 | 51,0 | 184 | 122 | 172 | 312 | 31,0 | 263 | 35 |

| 2-1/2 | 32,5 | 105 | 70,0 | 66,5 | 66,5 | 238 | 145 | 203 | 377 | 35,1 | 330 | 55 |

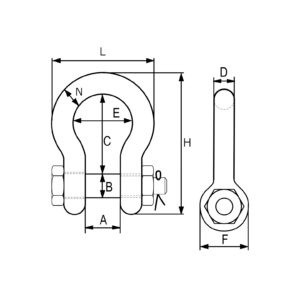

| Nominal Size (in.) D | Weight Each (kg) | Dimensions (mm) | Working Load Limit (tons) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | H | L | N | |||

| 3/16 | 0,03 | 9,65 | 6,35 | 22,4 | 4,85 | 15,2 | 14,2 | 37,3 | 24,9 | 4,85 | 0,33 |

| 1/4 | 0,05 | 11,9 | 7,85 | 28,7 | 6,35 | 19,8 | 15,5 | 46,7 | 32,5 | 6,35 | 0,50 |

| 5/16 | 0,10 | 13,5 | 9,65 | 31,0 | 7,85 | 21,3 | 19,1 | 53,0 | 37,3 | 7,85 | 0,75 |

| 3/8 | 0,15 | 16,8 | 11,2 | 36,6 | 9,65 | 26,2 | 23,1 | 63,0 | 45,2 | 9,65 | 1 |

| 7/16 | 0,22 | 19,1 | 12,7 | 42,9 | 11,2 | 29,5 | 26,9 | 74,0 | 51,5 | 11,2 | 1,5 |

| 1/2 | 0,36 | 20,6 | 16,0 | 47,8 | 12,7 | 33,3 | 30,2 | 83,5 | 58,5 | 12,7 | 2,0 |

| 5/8 | 0,62 | 26,9 | 19,1 | 60,5 | 16,0 | 42,9 | 38,1 | 106 | 74,5 | 17,5 | 3,25 |

| 3/4 | 1,23 | 31,8 | 22,4 | 71,5 | 19,1 | 51,0 | 46,0 | 126 | 89,0 | 20,6 | 4,75 |

| 7/8 | 1,79 | 36,6 | 25,4 | 84,0 | 22,4 | 58,0 | 53,0 | 148 | 102 | 24,6 | 6,5 |

| 1 | 2,28 | 42,9 | 28,7 | 95,5 | 25,4 | 68,5 | 60,5 | 167 | 119 | 26,9 | 8,5 |

| 1-1/8 | 3,75 | 46,0 | 31,8 | 108 | 28,7 | 74,0 | 68,5 | 190 | 131 | 31,8 | 9,5 |

| 1-1/4 | 5,31 | 51,5 | 35,1 | 119 | 31,8 | 82,5 | 76,0 | 210 | 146 | 35,1 | 12 |

| 1-3/8 | 7,18 | 57,0 | 38,1 | 133 | 35,1 | 92,0 | 84,0 | 233 | 162 | 38,1 | 13,5 |

| 1-1/2 | 9,43 | 60,5 | 41,4 | 146 | 38,1 | 98,5 | 92,0 | 254 | 175 | 41,1 | 17 |

| 1-3/4 | 15,4 | 73,0 | 51,0 | 178 | 44,5 | 127 | 106 | 313 | 225 | 57,0 | 25 |

| 2 | 23,7 | 82,5 | 57,0 | 197 | 51,0 | 146 | 122 | 348 | 253 | 61,0 | 35 |

| 2-1/2 | 44,6 | 105 | 70,0 | 267 | 66,5 | 184 | 145 | 453 | 327 | 79,5 | 55 |

| 3 | 70 | 127 | 82,5 | 330 | 76,0 | 200 | 165 | 546 | 365 | 92,0 | 85 |

| 3-1/2 | 120 | 133 | 95,5 | 372 | 92,0 | 229 | 203 | 626 | 419 | 105 | 120 |

| 4 | 153 | 140 | 108 | 368 | 104 | 254 | 229 | 653 | 468 | 116 | 150 |

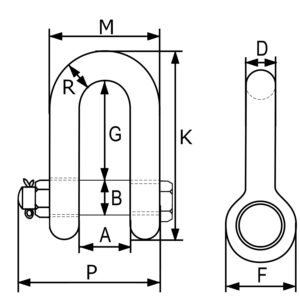

| Nominal Size (in.) D | Weight Each (kg) | Dimensions (mm) | Working Load Limit (tons) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | D | F | G | K | M | P | R | |||

| 1/4 | 0,06 | 11,9 | 7,85 | 6,35 | 15,5 | 19,1 | 40,4 | 24,6 | 39,6 | 6,35 | 0,50 |

| 5/16 | 0,10 | 13,5 | 9,65 | 7,85 | 19,1 | 25,4 | 48,5 | 29,5 | 46,2 | 7,85 | 0,75 |

| 3/8 | 0,15 | 16,8 | 11,2 | 9,65 | 23,1 | 31,0 | 58,5 | 35,8 | 55,0 | 9,65 | 1 |

| 7/16 | 0,22 | 19,1 | 12,7 | 11,2 | 26,9 | 36,1 | 67,5 | 41,1 | 63,5 | 11,2 | 1,5 |

| 1/2 | 0,34 | 20,6 | 16,0 | 12,7 | 30,2 | 41,4 | 77,0 | 46,0 | 71,0 | 12,7 | 2,0 |

| 5/8 | 0,67 | 26,9 | 19,1 | 16,0 | 38,1 | 51,0 | 95,5 | 58,5 | 89,5 | 16,0 | 3,25 |

| 3/4 | 1,14 | 31,8 | 22,4 | 19,1 | 46,0 | 60,5 | 115 | 70,0 | 103 | 20,6 | 4,75 |

| 7/8 | 1,74 | 36,6 | 25,4 | 22,4 | 53,0 | 71,5 | 135 | 81,0 | 120 | 24,6 | 6,5 |

| 1 | 2,52 | 42,9 | 28,7 | 25,4 | 60,5 | 81,0 | 151 | 93,5 | 135 | 25,4 | 8,5 |

| 1-1/8 | 3,45 | 46,0 | 31,8 | 28,7 | 68,5 | 91,0 | 172 | 103 | 150 | 31,8 | 9,5 |

| 1-1/4 | 4,90 | 51,5 | 35,1 | 31,8 | 76,0 | 100 | 191 | 115 | 165 | 35,1 | 12 |

| 1-3/8 | 6,24 | 57,0 | 38,1 | 35,1 | 84,0 | 111 | 210 | 127 | 183 | 38,1 | 13,5 |

| 1-1/2 | 8,39 | 60,5 | 41,4 | 38,1 | 92,0 | 122 | 230 | 137 | 196 | 41,1 | 17 |

| 1-3/4 | 14,2 | 73,0 | 51,0 | 44,5 | 106 | 146 | 279 | 162 | 230 | 54,0 | 25 |

| 2 | 21,2 | 82,5 | 57,0 | 51,0 | 122 | 172 | 312 | 184 | 264 | 60,0 | 35 |

| 2-1/2 | 38,6 | 105 | 70,0 | 66,5 | 145 | 203 | 377 | 238 | 344 | 66,5 | 55 |

| 3 | 56 | 127 | 82,5 | 76,0 | 165 | 216 | 429 | 279 | 419 | 89,0 | 85 |

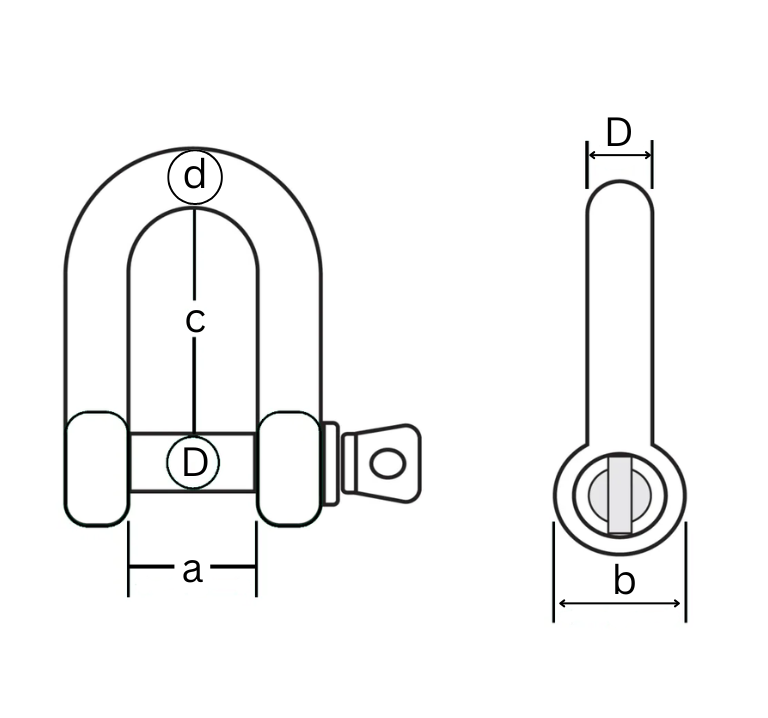

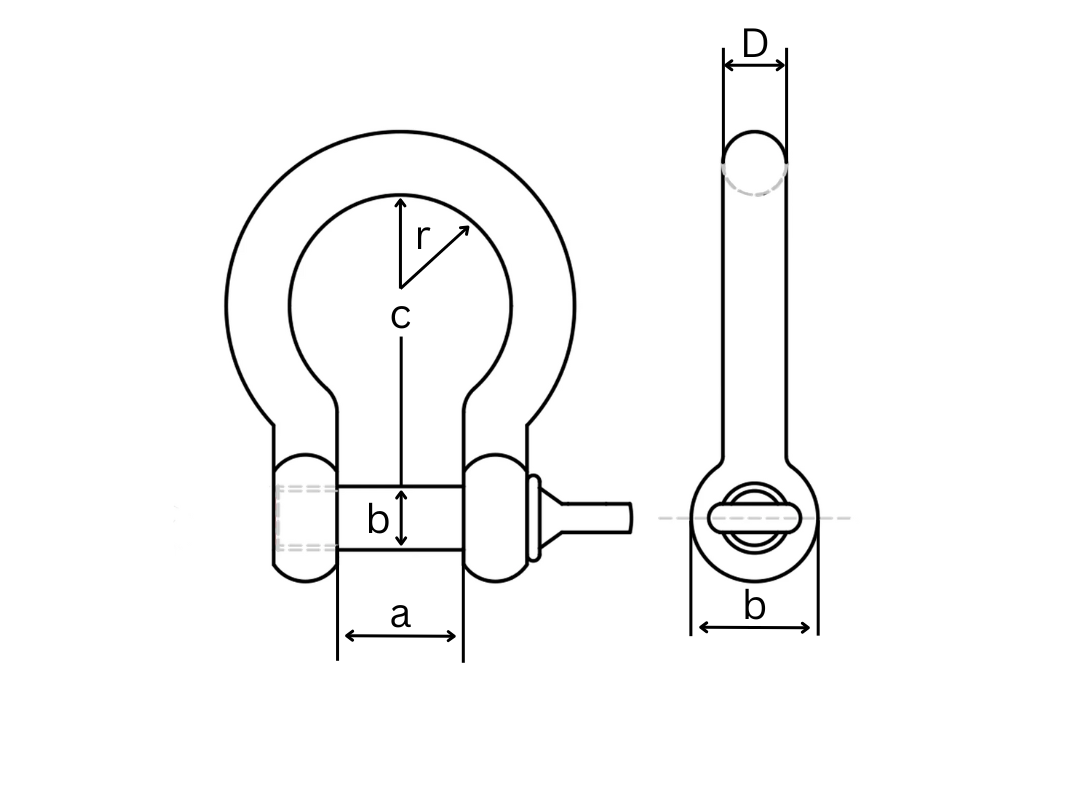

These shackles have equal sized pin and body. They are manufactured from mild steel which is left untreated, in grade 30, with galvanized finish. Not suitable for lifting operations. Fairly resilient and long-lasting in typical environments. With typical screw pin for securing. This makes them both easy to use and quick to fasten or unfasten. For applications where the shackle regularly needs to be removed or repositioned for whatever reason, this could be an advantage. Available in “D” & Bow types.

| SWL | D | d | a | c | b | Weight per 100 pce |

|---|---|---|---|---|---|---|

| kg | mm | mm | mm | mm | mm | kg |

| 80 | 5 | 5 | 10 | 19 | 11 | 1,9 |

| 100 | 6 | 6 | 13 | 25 | 14 | 3,4 |

| 200 | 8 | 8 | 16 | 32 | 18 | 7 |

| 320 | 10 | 10 | 19 | 38 | 20 | 13 |

| 520 | 12 | 12 | 25 | 51 | 26 | 24 |

| 800 | 16 | 16 | 32 | 64 | 33 | 50 |

| 1100 | 20 | 20 | 38 | 76 | 40 | 80 |

| 1500 | 22 | 22 | 44 | 89 | 50 | 130 |

| 2100 | 25 | 25 | 51 | 100 | 57 | 200 |

| 3000 | 28 | 28 | 57 | 115 | 68 | 300 |

| 3500 | 32 | 32 | 64 | 127 | 73 | 430 |

| 5000 | 38 | 38 | 76 | 152 | 85 | 675 |

| 7000 | 45 | 45 | 90 | 180 | 96 | 1250 |

| 8000 | 50 | 50 | 102 | 200 | 108 | 1750 |

| SWL | D | d | a | c | r | d | Approx 100 pce/WT |

|---|---|---|---|---|---|---|---|

| kg | mm | mm | mm | mm | mm | mm | kg |

| 80 | 5 | 5 | 10 | 19 | 8 | 11 | 1,9 |

| 100 | 6 | 6 | 13 | 25 | 10 | 14 | 3,4 |

| 200 | 8 | 8 | 16 | 32 | 12 | 18 | 7 |

| 320 | 10 | 10 | 19 | 38 | 16 | 20 | 13 |

| 520 | 12 | 12 | 25 | 51 | 19 | 26 | 26 |

| 800 | 16 | 16 | 32 | 64 | 28 | 33 | 50 |

| 1100 | 20 | 20 | 38 | 76 | 33 | 40 | 80 |

| 1500 | 22 | 22 | 44 | 89 | 37 | 50 | 130 |

| 2100 | 25 | 25 | 51 | 100 | 40 | 57 | 200 |

| 3000 | 28 | 28 | 57 | 115 | 47 | 68 | 310 |

| 3500 | 32 | 32 | 64 | 127 | 52 | 73 | 430 |

| 5000 | 38 | 38 | 76 | 152 | 63 | 85 | 700 |

| 7000 | 45 | 45 | 90 | 180 | 75 | 96 | 1250 |

| 8000 | 50 | 50 | 102 | 200 | 78 | 108 | 1750 |

| Side Loading Reduction Chart For Screw Pin and Bolt Type Shackles | |

|---|---|

| Angle of Side Load from Vertical In-Line of shackle | Adjusted Working Load Limit |

| 0° In-Line * | 100% of Rated Working Load Limit |

| 45° from In-Line * | 70% of Rated Working Load Limit |

| 90° from In-Line * | 50% of Rated Working Load Limit |

* In-Line load is applied perpendicular to pin.

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our Cookie Policy.