In industries that heavily rely on steel wire ropes for industrial-scale and heavy-duty applications, regular lubrication is a crucial maintenance practice. This lubrication serves two primary purposes: enhancing safety and extending the lifespan of the wire rope by up to 300%.To ensure the correct application of high-performance lubricants, particularly for penetrating the greases into the wire rope and its core, the use of a pressure lubricator is the most effective method. pressure lubricators are specifically designed to ensure that the lubricant is evenly distributed throughout the wire rope, including its inner strands and core.

The advantages of using a pressure lubricator include:

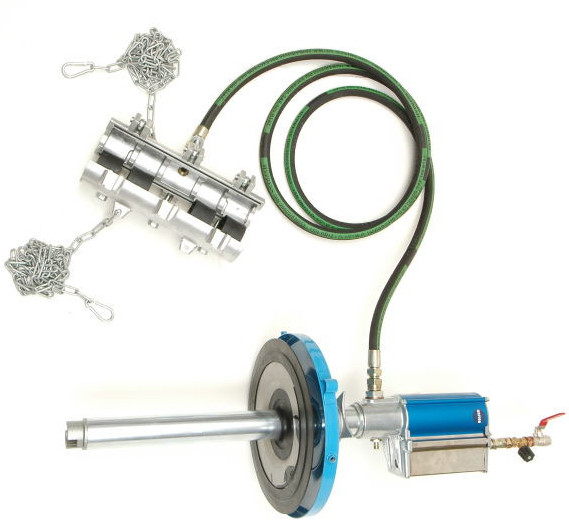

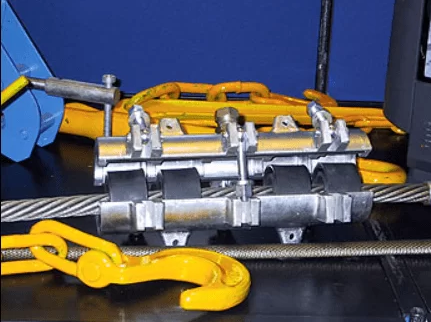

The Pressure Lubricator is easy to use. Split seals are fitted around the rope and clamped in place by the two halves of the lubricating chamber.

The unit is coupled to a high-pressure lubricating pump via flexible hose, and lubricant is forced into the lube chamber.

The unit is anchored by two chains to a convenient, stationary object. The pump is started and the wire rope is pulled through the Lubricator.

Katradis S.A. recommends using Environmentally Acceptable Lubricants (EALs) that comply with the Vessel General Permit (VGP) due to their reduced environmental impact and adherence to rigorous standards. These lubricants must meet the following criteria:

Katradis S.A. is capable of supplying lubricants that meet these criteria and are fully compliant with the VGP. For specific applications and more detailed recommendations, it is advisable to contact the company directly.

The combination of these properties makes such lubricants ideal for harsh maritime or industrial applications, ensuring reliable performance, environmental safety, and compliance with regulatory standards.

Subscribe to our newsletter

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our Cookie Policy.