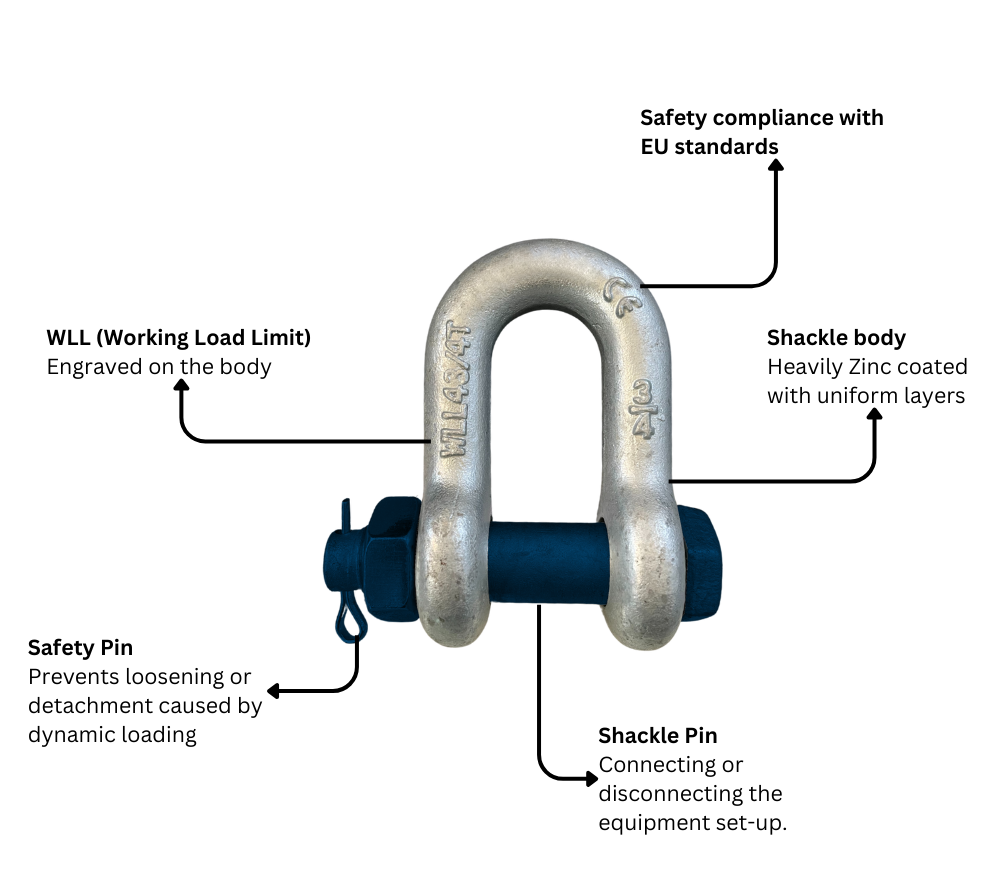

The appropriate selection of shackles is critical to ensuring safety in applications such as anchoring, lifting and rigging. Factors like load capacity, material, and corrosion resistance determine whether a shackle can meet the demands of its intended use. Katradis HP Shackles, as highlighted in our recent study with National Technical University of Athens (NTUA), are an example of high-quality components designed for durability in demanding environments, particularly maritime and heavy-duty industries.

Designing a high-quality shackle needs the correct material selection, adequate surface coating to protect from corrosion, high loading capacity and low surface roughness. The key mechanical properties of KATRADIS HP Shackles have been tested by the Metallurgy and Materials Technology Laboratory of NTUA. Galvanized steel samples obtained from competition shackles were also selected for a comparative study and analysis of the findings.

Katradis HP Shackles displayed tempered martensite with evidence of heat treatment at higher temperatures (450–600°C). A ferrito-pearlitic structure, characterized by carbon content in the range of 0.35–0.40 % is ideal for dynamic load resistance and improved performance. This structure can better absorb impact energy, making it less likely to crack/deform under stress.

Competition samples revealed tempered martensite from lower-temperature heat treatment (200–250°C), leading to reduced uniformity. A ferrito-pearlitic microstructure with slightly lower carbon content (~0.30%), indicating differences in processing methods. Its microstructure indicates similar toughness but less tensile strength.

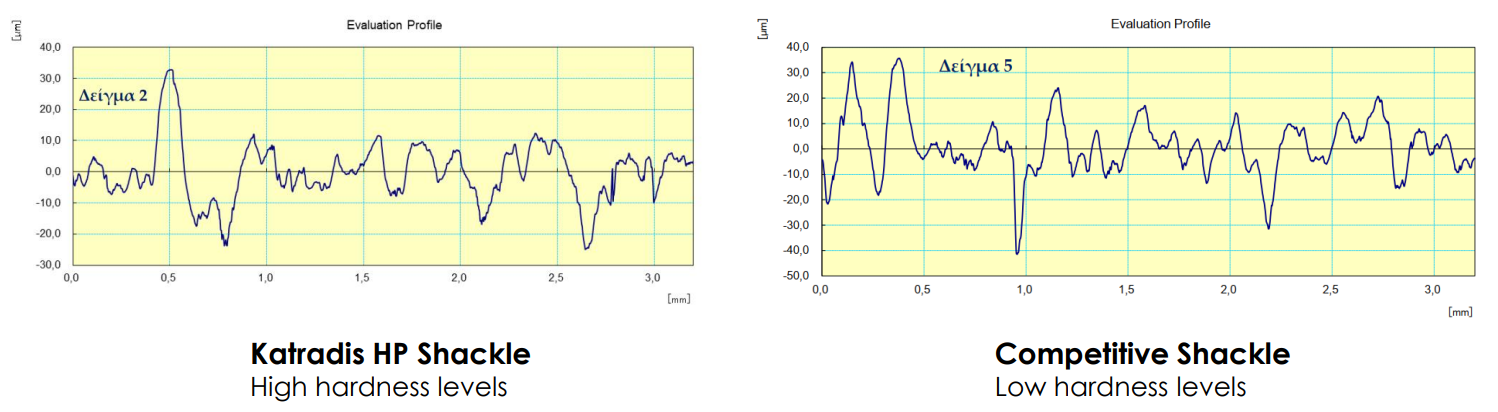

Katradis HP Shackle shows superior hardness levels of 300 HV, corresponding to a tensile strength of approximately 950 Mpa.

Competition samples showed moderate hardness (~227-240 HV), indicating moderate tensile strengths (~740-770 MPa).

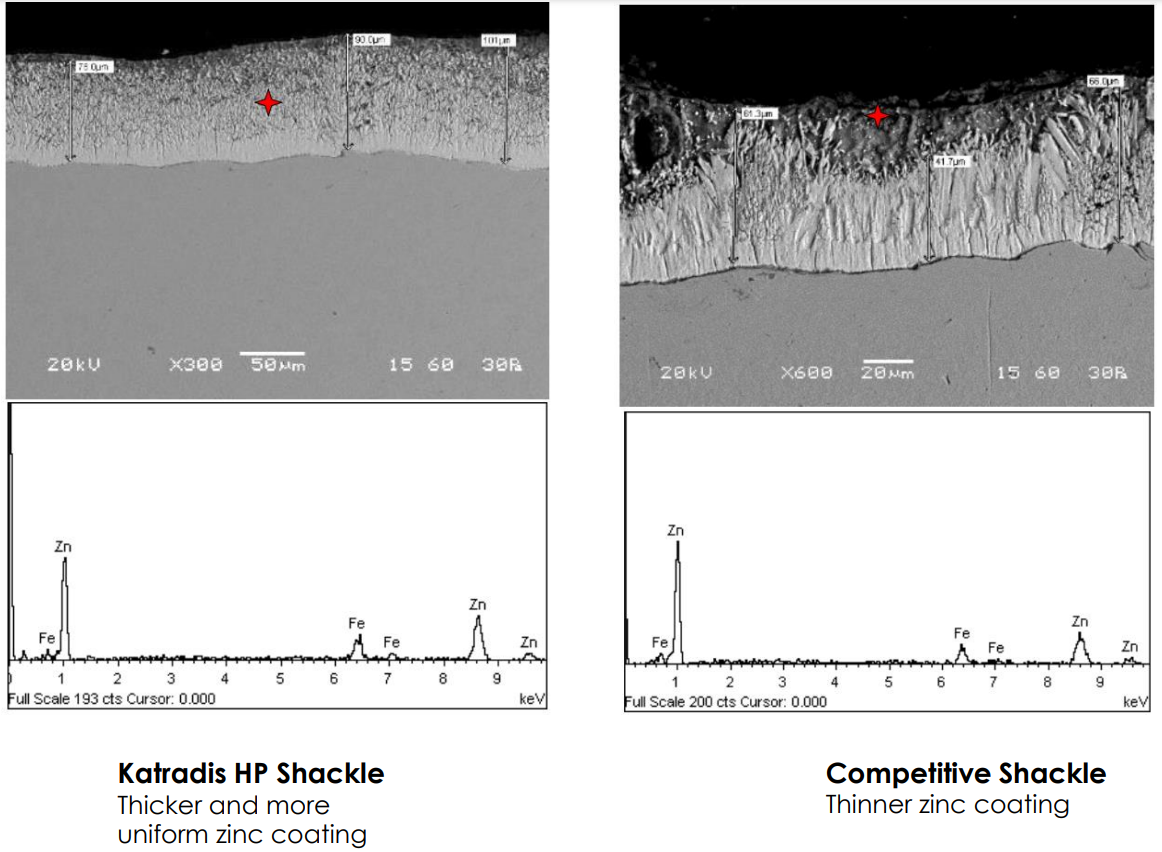

Katradis HP Shackle has thicker coating (80-90 μm) and more uniform. This not only provides better protection against corrosion but also ensures consistent performance across the material’s surface.

Competition samples exhibit thinner (40-50 μm) and showed inconsistencies like porosity and voids, which could accelerate corrosion and reduce the material’s lifespan in harsh environments.

Katradis HP Shackle has smoother surfaces (~0.5-1 μm), enhancing corrosion resistance. Optimized roughness creates a surface texture that allows the zinc galvanizing to adhere more effectively.

Competition samples revealed rougher surfaces (up to 12 μm)

Katradis HP Shackles display superior structural consistency, with well-balanced hardness and toughness, and better surface finishes and coatings. These attributes enhance durability and performance, making them superior to market alternatives.