Synthetic rope manufacturing is a highly specialized process that combines proper selection of polymer materials, precision engineering and advanced processing methods to produce high-quality ropes for marine, industrial, and offshore applications. At KATRADIS Marine Ropes Industry, we utilize state-of-the-art technology and adhere to ISO standards to ensure that our ropes deliver maximum strength, durability, and safety.

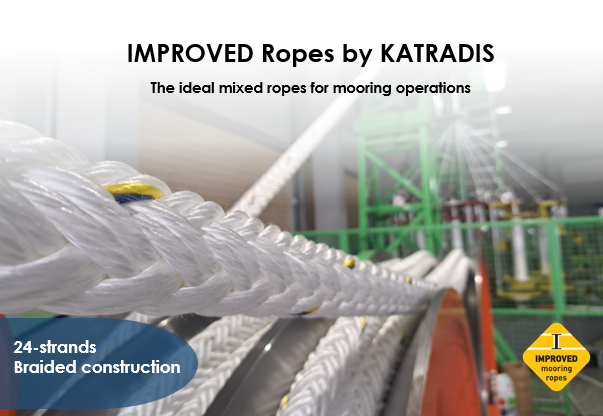

IMPROVED mixed ropes combine the benefits of polyolefin fibers and polyester fibers in the outer layers into a balanced construction that capitalizes on the properties of both materials:

The developed 24-strand configuration results in a rope that is not only lightweight and easy to handle, but also resilient to harsh maritime conditions, reducing the risk of accidents and increasing lifespan.

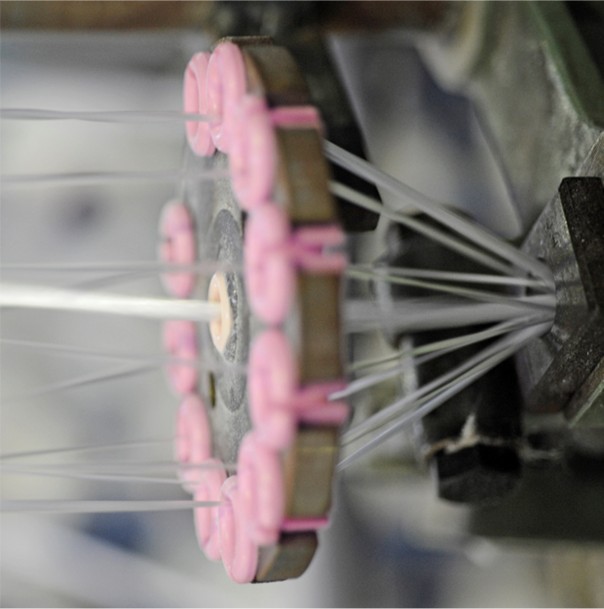

Yarn composition plays a critical role in the performance and durability of synthetic ropes. Proper twisting methods increase the yarn abrasion resistance, enhance energy absorption during dynamic loads, and extend the rope’s service life. This manufacturing process adheres to ISO 10556, which specifies the construction, testing, and performance characteristics of fiber ropes used in mooring and towing applications.

Rope yarn with Polyester fibers covering the polyolefin NIKA-Steel® core fibers according to ISO 10556

(Fibre ropes of polyester/polyolefin dual fibres)

The good practice of the rope braiding ensures the rope’s internal and external fibers are uniformly aligned and tensioned. Proper and consistent laylength and braiding angles provide the required balance of the rope structure to operate in the mooring conditions and sudden loads.

Laylength: the linear distance required for a strand or braid to complete one full helical turn around the rope’s axis. Designing the effective laylength is a factor that can increase the durability of the rope.

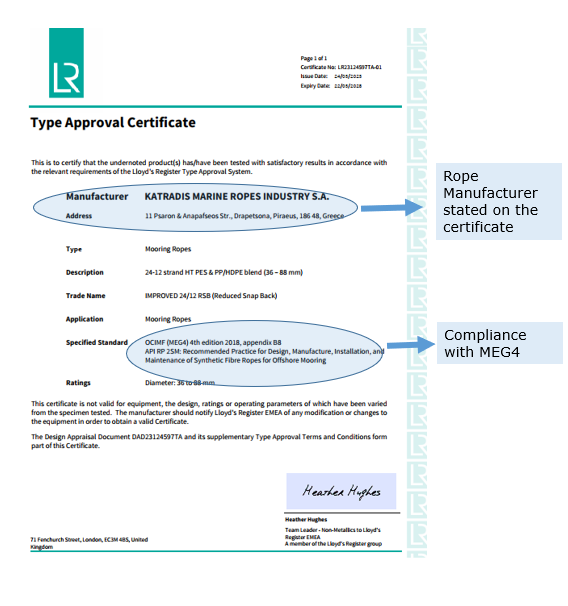

International guidelines such as MEG4 and IMO SOLAS circulars aim to enhance safety, performance, and longevity of mooring lines used on oil tankers, gas carriers, and terminals. All the required testing for compliance with MEG4 is performed in-house through our fully equipped Quality Department and expertized technical staff. Certification and Type Approval process of our ropes is under IACS classification society.

Testing Requirements for Mooring Lines

Testing Requirements for Mooring LinesAngled Break Force as per MEG4 Testing in KATRADIS laboratory

When it comes to MEG4 compliance, it is very crucial for the end user to receive the correct certificates for both mooring lines and tails by the Rope Manufacturer.